|

DC

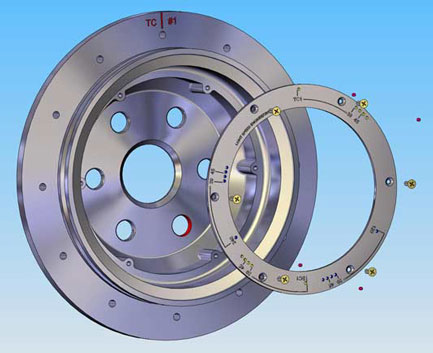

Mini Sensor and Magnet Ring |

|

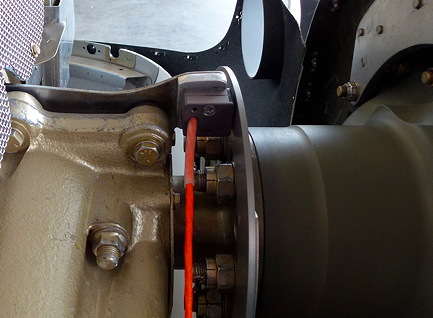

On

Lycoming Engines, a Magnet Ring is

installed in the flywheel to provide the

trigger for either a single or a

dual Mini Sensor installation.

|

|

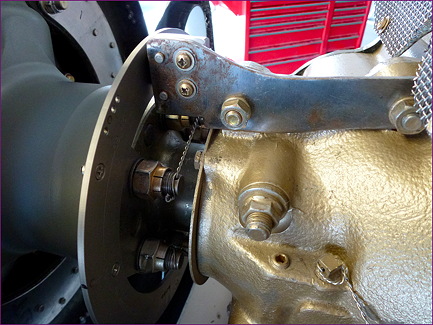

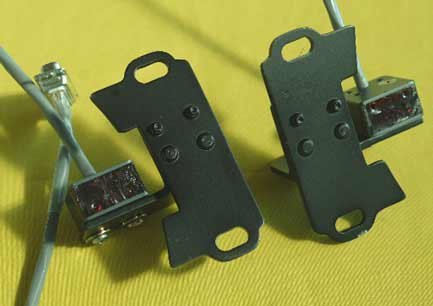

DC

Mini Sensor and Lycoming Mounting Bracket

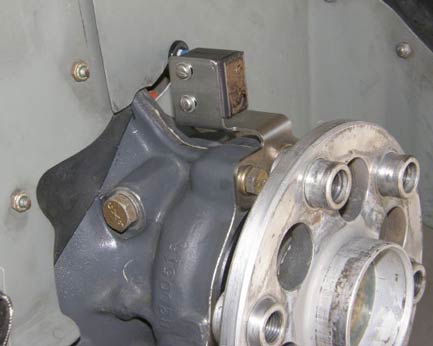

The

sensors are completely sealed and potted

in their billet machined aluminum

protective enclosures and mounted on

stainless steel brackets.

|

|

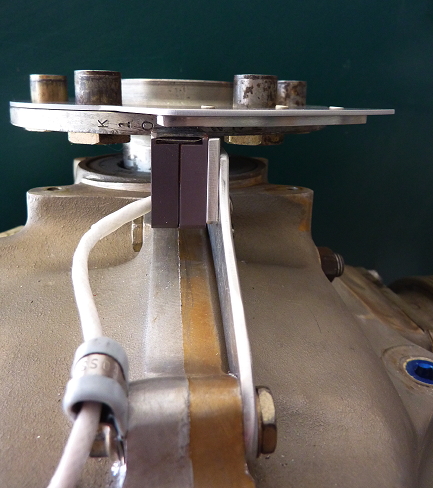

DC

Mini Sensor Installed on a Lycoming 360

in John Lynch’s RV-4.

The

Mini Sensor stainless steel mounting

bracket fits to the engine crank case.

|

|

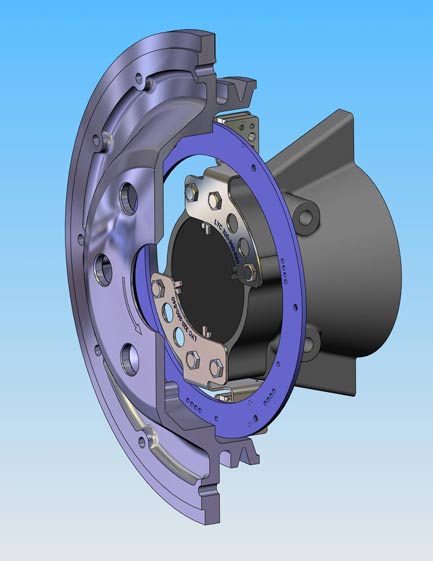

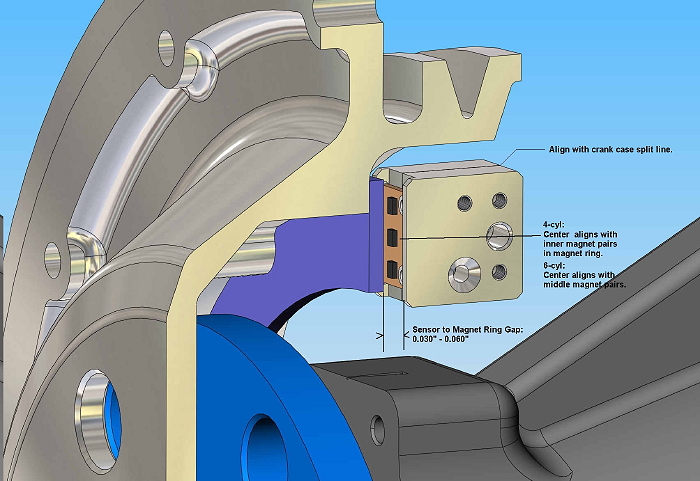

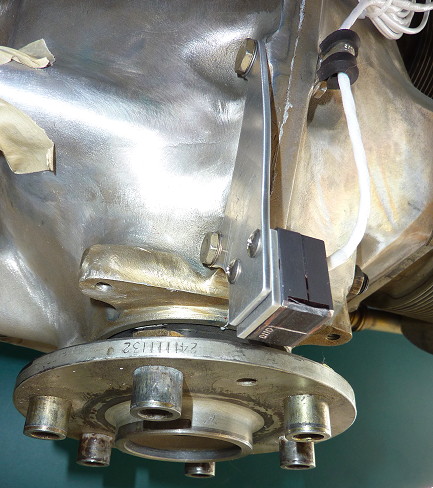

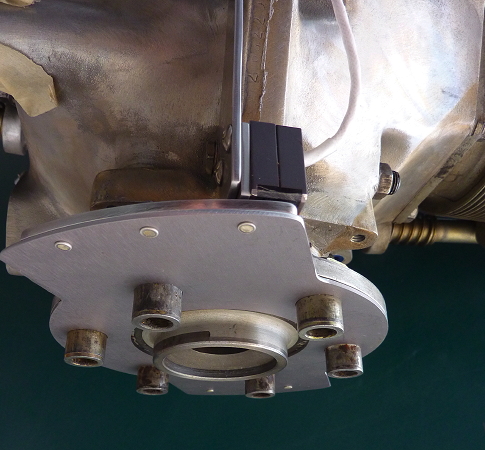

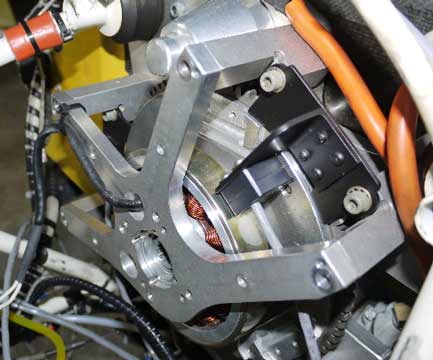

Lycoming

Engine: 4-cylinder Dual DC Mini Sensor

Installation

Single

systems require only one Mini Sensor.

On dual 4 cylinder engine

installations, there are two Mini Sensors

at 180 degree intervals. On dual 6

cylinder installations, a second Mini

Sensor is mounted 120 degrees from the

first.

|

|

|

|

| The

mini sensor blocks can be mounted on

almost any radius, which provides great

flexibility in mounting options for all

engine types. |

|

|

|

Continental

6-cylinder Engines:

The

following pictures are Mini Sensor parts

and installation on a Continental 550

engine. |

|

DC

Mini Sensor Magnet Ring for Continental

6-cyl. Engines |

|

Single

Mini Sensor Installed in the Top Position

on Jerry Mercer's Continental 550 Questair

Venture |

|

The

mounting bracket for the top position Mini Sensor

on Jerry Mercer's

Continental 550 Questair Venture |

|

|

|

|

|

Continental

O-200 Engines:

|

|

Continental

O-200 Mini Sensor installation on the top

of the engine. The trigger magnet

bracket is not installed in this picture

in order to provide a clear view of the

mini sensor mounting bracket. |

|

Top

Mini Sensor on O-200 with the Trigger

Magnet plate installed. |

|

Mini

Sensor installed on the bottom of the

Continental O-200 to provide the trigger

to the second system in a Dual Plasma CDI

installation. On Dual 4-cylinder

installations, there are two mini sensors

installed at 180 degree

intervals. |

|

|

|

|

|

Jabiru

Engines:

Here

are pictures of the Dual Mini Sensor

installation developed by Henri Malerba

for his 240mph Vari Eze.

On

Jabiru engines, the trigger magnets can be

installed directly into the aluminum

flywheel.

No Magnet Ring is needed.

Light

Speed Engineering provides drawings for

all Jabiru brackets. |

|

Original

Jabiru Coil Mounts with LSE Mini Sensors |

|

Jabiru

Engine:

Mini Sensor Facing the Aluminum

Flywheel |

|

|

|

|

|

Franklin

Engines:

Here are

pictures of the Franklin Engine using the

new DC Mini Sensor.

Mini

Sensors are readily available but are not

currently supplied with Franklin mounting

brackets and magnet ring.

Light Speed Engineering provides

drawings for all Franklin brackets and the

magnet ring.

|

|

Franklin

Engine: 6-cylinder

Dual DC Mini Sensor Installation

Integration

to the Franklin Engine designed,

installed, and photographed by John

Burnaby. |

|

|

|

|

|

|

|

|

|

|

|

Technical

Description of the Mini Sensor Concept

The

Mini Sensor consists of two billet

aluminum machined halves that capture a

small circuit board holding 3 Hall effect

sensors at 0.250” spacing.

For environmental protection, they

are completely sealed and potted.

On 4-cylinder engines, only the

outer and middle sensors are used.

The

Magnet Ring has two magnets installed on

the same radius as the outer sensor.

Another two magnets are installed

on the same radius as the middle sensor

(0.250” less). On 4-cylinder Magnet Rings, this second set of magnets is

located 180 degrees from the first set.

On 6-cylinder Magnet Rings, this

second set of magnets is located 120

degrees from the first set. Additionally, 6-cylinder Magnet Rings have another two

magnets mounted on the same radius as the

third (inner) sensor (0.250” less than

the second pair and 0.50” less than the

first pair). This third set of magnets is located 240 degrees from the

first set.

Mounting

the Magnet Ring

to the Lycoming flywheel requires drilling

and tapping 6 holes. For best

precision this should be done on a CNC

machine or on a precision fixture at

Light Speed Engineering. The

flywheel modification and magnet ring

installation is $95 plus shipping.

Alternatively, pre-drilled flywheels are

available for purchase from Continental

Motors, formerly ECi, or Lycoming

Thunderbolt division upon

request.

|

|

|

|

|